Understanding Spot Marks in Double Glazed Units (DGUs)

craftpresence7@gmail.com

December 9, 2024

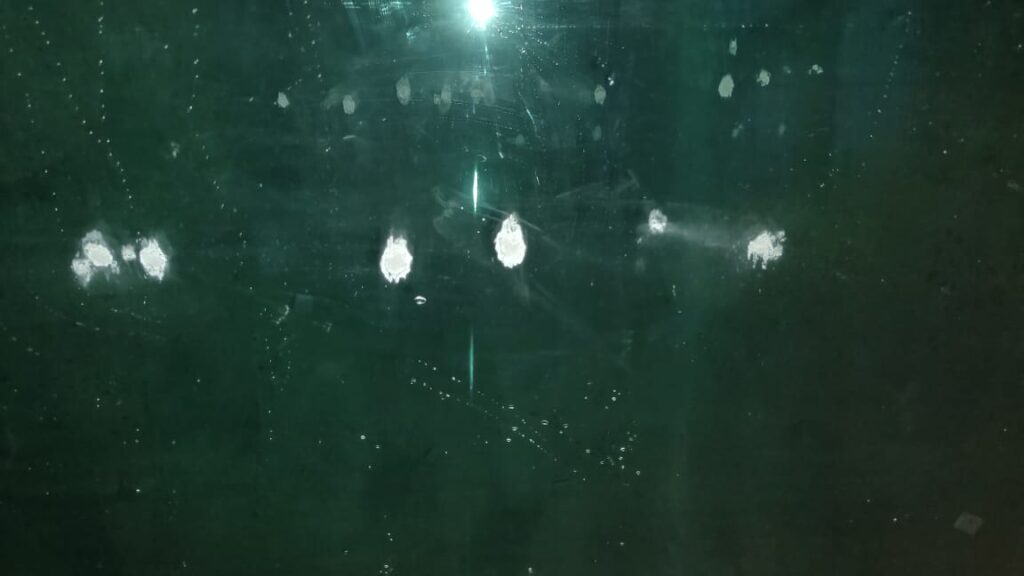

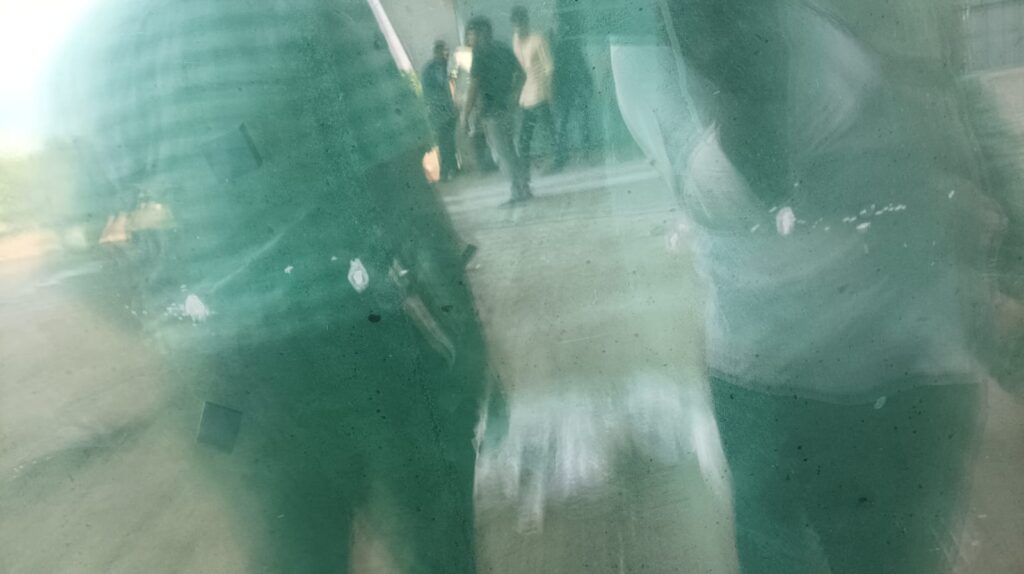

Spot marks on Double Glazed Units (DGUs) can detract from the aesthetic quality of glass and often indicate underlying issues related to design, handling, or installation. These marks typically form when the inner surfaces of the glass panes come into contact with one another. Common causes include vibrations during transportation and wind pressure after installation. A primary contributing factor is the improper design of the air gap between the panes, which should be carefully calculated based on the size and thickness of the glass. This article explores the causes of spot marks in DGUs and offers practical solutions to prevent them.

Causes of Spot Marks in DGUs

1. Improper Air Gap Design

All glass panels have some level of flexibility, which is reduced as the thickness of the glass increases. For example, a 5 mm thick glass panel is more flexible than a 12 mm thick one. Thicker glass panels are less likely to deform under external forces, resulting in less deviation at the center of the pane.

The dimensions of the glass panel, including its height and width, are also crucial. Larger panels, especially those with square proportions, experience greater central deflection. As a result, the design of the air gap between the panes must be carefully considered to accommodate these variables.

To avoid spot marks and ensure optimal performance, the air gap in a DGU should be calculated based on several factors:

- Glass thickness: Ensuring the correct thickness for structural stability.

- Height-to-width ratio: The panel’s overall dimensions influence its behavior.

- Total glass area: The size of the entire panel impacts deflection.

- Wind pressure: Local wind load conditions should be factored into the design.

Accurately assessing these parameters ensures the air gap is appropriately sized, preventing issues like spot marks and improving the longevity and performance of the DGU.

2. Vibrations During Transportation

During transportation, DGUs are exposed to vibrations from road conditions and the pressure of being stacked. Without proper care in packaging and handling, these vibrations can cause the glass panes to come into contact, leading to the formation of spot marks.

To prevent this, consider the following measures:

- Minimize the angle of inclination: Ensure that the glass is stacked with the least possible tilt when loading it onto the vehicle.

- Use Argon gas for large units: For long-distance shipments, it’s essential to fill the air gap with Argon gas to help maintain structural integrity.

- Thicker spacers: Using thicker spacers between the edges of the glass panes during transport can reduce the risk of contact between the inner surfaces.

- Improper Stacking (Too Heavy or Too Many Layers):

Improper stacking occurs when too many glass units are piled on top of each other or when the weight of the stacked units exceeds their capacity. This can create high pressure on the units below, which may cause the glass to touch and leave marks on the lower layers of the double-glazed units (DGU).

3. Wind Pressure After Installation

After DGUs are installed, they can be exposed to wind pressure, especially in high-rise buildings or places near the coast. Strong winds can cause the panes to move if the air gap is too small and continuous touching and vibration lead to spot marks.